Search

The BUCHEN-ICS Group’s locations

The whole picture – with just a single click. Find out here where our branches are located, what services they offer and how to contact them.

The REMONDIS Group’s business locations

The addresses of all of the REMONDIS companies and branches can be found at:

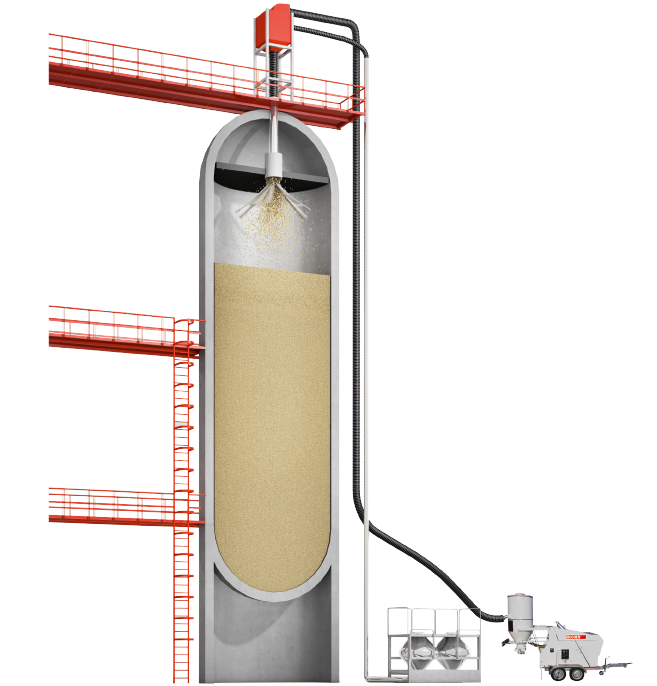

Always safe whatever the weather

Thanks to our material-friendly dense phase conveying system, we are able to fill reactors and other vessels with catalyst or bulk materials without interruption wherever a crane may not be used for safety or weather reasons.

Additional information can be found here: both our brochure and our video on our dense phase conveying system can be downloaded

Defying the whims of the weather

The standard way of transporting catalyst is to bring in a crane to lift up the material (packed in big bags or flow bins) and place it next to the opening. This means, however, that a large area must be cordoned off around the lifting area to create a safety zone below the suspended loads. Even with these safety zones, though, the work must be stopped if it rains too heavily or the wind gets too strong. This can all be avoided with our dense phase conveying system. With the two storage tanks on the ground, the filling container at the opening to the reactor/vessel and the hose lines all being completely weatherproof, the material can be transported and kept dry throughout the process.

Any place, any time

The dense phase conveying system is suitable for all types of reactors and vessels. We can fill your reactors in CCR, HC, Claus and styrene plants no matter the weather – even in strong winds and heavy rain. What’s more, we can use our system for molecular sieve vessels and HDS reactors as well as vessels in ethylene/propylene hydrogenation plants. The lack of space at a PSA plant, which has up to six vessels placed next to each other, is no longer a problem either thanks to our dense phase conveying system.

Advantages

No need to use a crane for the loading process

No need to interrupt the work in bad weather

The material can be transported with nitrogen instead of compressed air if this is necessary

A flexible system: it is transported in a 20ꞌ container and can be installed quickly and easily at the work site

The material can be conveyed vertically up to 90m above ground – depending on the size, shape and weight of the catalyst

The electronic control system can be switched to manual control in the case of an emergency

Dust particles are vacuumed up during the filling process

Catalyst handling technology

We not only use standard technologies (such as industrial vacuum cleaners and material-friendly catalyst screening equipment) but also processes which we have developed ourselves to make our work even safer and more efficient. Details about a number of these technologies can be found below.

Our catalyst handling systems

Life support system (CE 0158)

Our CE-certified life support system (LSS) meets the highest safety standards and is deployed when operatives carry out tasks in a nitrogen atmosphere. This system has a number of advantages: video surveillance is available at all times (also in the LSS control centre itself) and the infrared technology enables the atmosphere and lower explosive limit (LEL) to be continuously measured. It also uses ‘anti-panic helmets’, which have two completely separate oxygen supplies, and an integrated communications system. What’s more, the system is extremely flexible as it can be transported in many different ways (trailer, bus, flight case etc).

- An anti-panic helmet with two completely separate oxygen supplies, based on a product developed by NASA

- Permanent video surveillance of the reactor technology

- The integrated communications system enables the oxygen supervisor, the technician assisting the operative wearing the helmet and the operative in the reactor to communicate with each other

- HC and O2 measuring equipment makes the work even safer for both the people and the plant and enables the LEL to be monitored

- Documentation system: a camera and recording device able to be used in explosion-risk zones

Dense loading system

In some cases, it is extremely important for the catalyst to be distributed evenly in a reactor while it is being loaded. This is where the dense loading technology comes into play. This system has a series of rotor blades that regulate the way the material falls into the reactor. We offer all conventional dense loading systems.

Dust-free catalyst handling

The systems we use (run using either compressed air or nitrogen) fill the catalyst into 200l drums – a process that takes, on average, just 15 seconds per drum. A sliding valve automatically closes each time to prevent a spill and a sensor in the lid stops the drums from being overfilled.

Screening equipment

- Classification methods: tumbler screening machine or vibration screening machine

- Highly efficient: the catalyst material is screened into up to five fractions

- Use of different mesh sizes to meet individual customer requirements

Vacuum and pre-separator units

Vacuum unit

- Suitable for work carried out under inert conditions with a fine filter, safety filter, double-flap valve, nitrogen cooler and recirculation of nitrogen

- Motor capacity: 240-320 kW

- Suction capability: 6,000-10,000 m3/h

- Suction performance: 90%

Catalyst-friendly pre-separator unit

- Catalyst handling equipment for loading and unloading work

- A continuous flow of gas throughout the system prevents the catalyst breaking up